6 steps to get higher bid scores

“Think before you start” is an invitation to vendors to prepare themselves better before applying to a (Best Value) tender. Know what your strengths are, be sure that you can substantiate this and identify what you are not good at. The result is a performance-oriented organization that gets higher scores in tenders. Below we briefly explain these benefits and show you how to achieve this in simple steps.

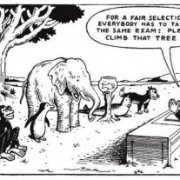

Knowing what you are good at and what not, is all about making choices.

This means that you do not try to do everything, or a little bit of everything, but clearly identify a fit between your strengths and specific clients. We call this your proposition. If you have a clear proposition, then it is easier for you to distinguish between tenders that are not suitable for you and those that are. It will increase your scoring opportunity and hit rate for tenders and your projects become more successful because you focus mainly on projects that have a fit with your key strengths. Or in Best Value terminology: Your expertise fits the client’s objectives, you are able to take responsibility and execute the project successfully and profitably.

In practice we see that in tenders vendors find it difficult to take on the expert role.

Most of the time the applied motto is “the client asks, we deliver”. In addition, the vendor assumes that every client’s request is unique. We experience the opposite. For example: the majority of clients who tender for a construction project want it to be as energy-durable as possible, executed with the least possible nuisance to local residents and having a high level of user satisfaction after completion. If these client objectives are general, it is therefore not necessary for the vendor to reinvent his proposition with each tender. A Best Value vendor should analyze the client objectives and determine what value he can add, knowing his proposition, before tenders come in.

Tips to improve your bid score

Below we present 6 steps that lead to a proposition that can be used for Best Value tenders and in any tender, to improve your scores:

- Determine the strengths of your organization / products and which partner expertise is utilized

- Divide your clients into client segments based on corresponding client characteristics

- Make a list of the most common objectives per client segment (max 8)

- Link your strengths to the client objectives: the performance statements and proposition

- Search within the client segment for metrics / performance information that supports the claims (start tracking performance if there are none)

- Make an overview of all objectives and substantiated performance statements that can be used in the selection of the most suitable tenders and answering them

Implementation advice

We have guided various organizations in different industries (like IT and construction) through these steps to come up with a proposition, a set of performance statements per client segment. The most challenging part of this was making the dominant strengths of the own organization concrete. These organizations are satisfied with the result, the overview of dominant strengths that defines the quality of the organization and the value that it provides, in concrete terms, for their customers. Their tender process has become simpler, efficient and effective. In particular the definition of performance and the search for metrics and performance information has improved. It has led them to get higher scores on bids in tenders.

Do you also want to get better scores on bids in tenders? And get started to define a proposition for your organization or products? Do you want to be guided through the steps successfully? Contact us.